Design & Tech

From Evolution to Revolution: The Modern Microplate Reader

Introduction

The microplate reader was first introduced in the late 1970s. While the applications today are practically endless, the first microplate readers were designed to read absorbance in 96-well format, with their first significant application being the Enzyme-Linked Immunosorbent Assay or ELISA. Since then, various technological advancements have allowed for more sophisticated methods and convenient usage. Looking at the modern microplate reader today, it has little in common with its predecessors. Essentially, two technological developments have bolstered this progress: the adoption of LED technology and the abolishment of scanning mechanics. The transition to LEDs as the primary light source for microplate readers has been unfolding over the course of the last decade, whereas implementing alternatives to scanning mechanisms has just begun. This paper discusses these two technological advancements and outlines why the slow evolutionary progress has recently been upset by a revolutionary leap forward. Throughout the paper, microplate readers implementing the combination of these technologies (LEDs and scan-free readout) are referred to as solid-state readers (SSR).

Technological impact

Light source

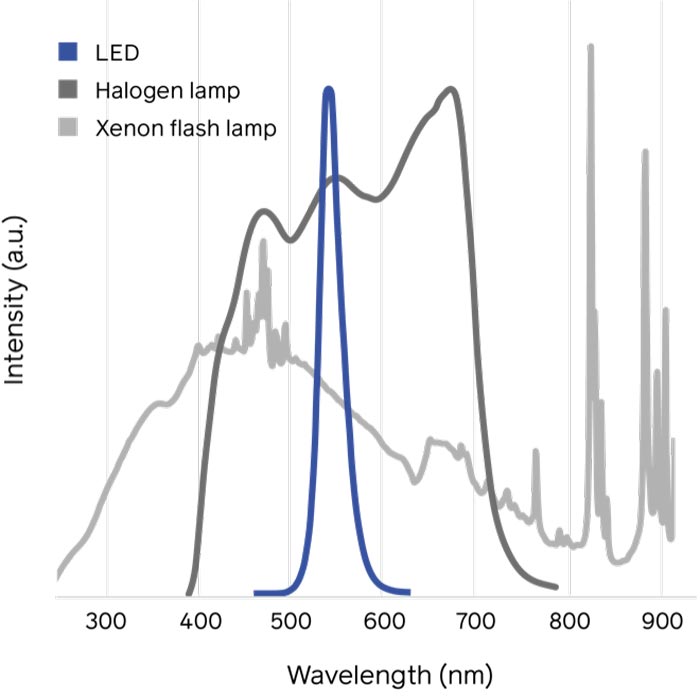

Over the years, the technology of different light sources has evolved and offered increasingly advanced options, such as halogen, tungsten, deuterium, and Xenon flash lamps, as well as LEDs. In Fig. 1, a comparison of the most frequently used light sources for microplate readers is shown. As can be seen in Fig. 1, the Xenon flash lamp has the broadest spectrum and is hence best suited to readers operating in the UV (ultraviolet) range. Halogen lamps, however, while offering no light emission in the UV range, are the more affordable light source and can be found in basic readers measuring in the VIS (visible) range. The spectral coverage of today’s state-of-the-art LEDs starts at around 340nm and extends into the IR (infrared) range. Despite their limits in the UV range, LEDs represent superior technology.

Figure 1: Comparison of light source spectra used in most microplate readers

First to mention is their longevity. A typical LED can be operated for more than 20.000 hours before a loss of intensity is observed. However, in the case of a micro-plate reader, the LED is only used briefly during the readout process, typically limited to a few seconds. Due to this minimal usage time, it can be assumed that the LED’s lifetime will surpass the reader's lifetime, thereby precluding the need to change the light source. This is the first step towards a maintenance-free microplate reader.

A second key feature of LED technology is its energy efficiency. LEDs are more than 85 % more efficient than a typical halogen lamp. Their emission spectrum can also be tailored to the wavelength of the desired filter, which makes them even more efficient and desirable for a microplate reader. The ability to tailor the wavelength results in reduced energy consumption overall and, more importantly, less heat generation. As LEDs reach their full brightness instantly, no warm-up time is needed and the readout can be started immediately after turning the reader on.

Due to the aforementioned benefits, most plate reader manufacturers have begun to offer LED-based microplate readers, such as the Tecan Infinite f50, Biochrom EZ Read LED, or the Byonoy Absorbance 96 microplate reader.

Solid-State Reader

The convenience of having 96 or more wells in which to perform a given assay has resulted in a challenging task for microplate reader manufacturers. The traditional approach to measuring 96-well microplates involves moving each well of the microplate to the detection unit. This requires each well of the microplate to be brought underneath a single detection channel, where the well is then measured, and the next well in the sequence is brought to the detector. This type of readout requires a scanning system consisting of a two-axis motor. These scanning systems have the disadvantage of adding an additional level of complexity to the reader and demand space and an adequate energy supply. Furthermore, during the readout, fast movements can affect the meniscus of the fluid and result in poorly reproducible results.

To achieve a faster readout, the single detection unit consisting of a light source coupled to an optical fiber and a photodiode has been mostly replaced by multi-unit detectors. 4, 8, and 12 detection units are common multi-unit formats. While this allows for more rapid measurement, these multi-unit detectors still require a scanning mechanism.

In contrast to these traditional methods, recent progress in miniaturization and manufacturing have made it possible for microplate readers to be built in the absence of such a scanning mechanism. This type of reader is outfitted with 96 individual detection units. This technological redesign has made it possible to develop a microplate reader with a footprint about the same size as the microplate itself. All 96 detection units are placed at a fixed position, meaning that a positioning misalignment during the lifetime of the reader cannot occur. Readout occurs in a solid-state manner, whereby each well of a 96-well microplate is addressed by a multiplexing electronic. This allows for a simultaneous readout of all wells. During the measurement, the microplate and hence the meniscus remain still and constant, which yields more reliable and reproducible results. The multi-unit design also increases the measurement speed; a typical measurement can be performed within a few seconds. This emerging technological approach is currently implemented in the Byonoy Absorbance 96 plate reader.

Benefits

These two technological advancements result in a series of benefits that characterize the modern microplate reader.

Compactness

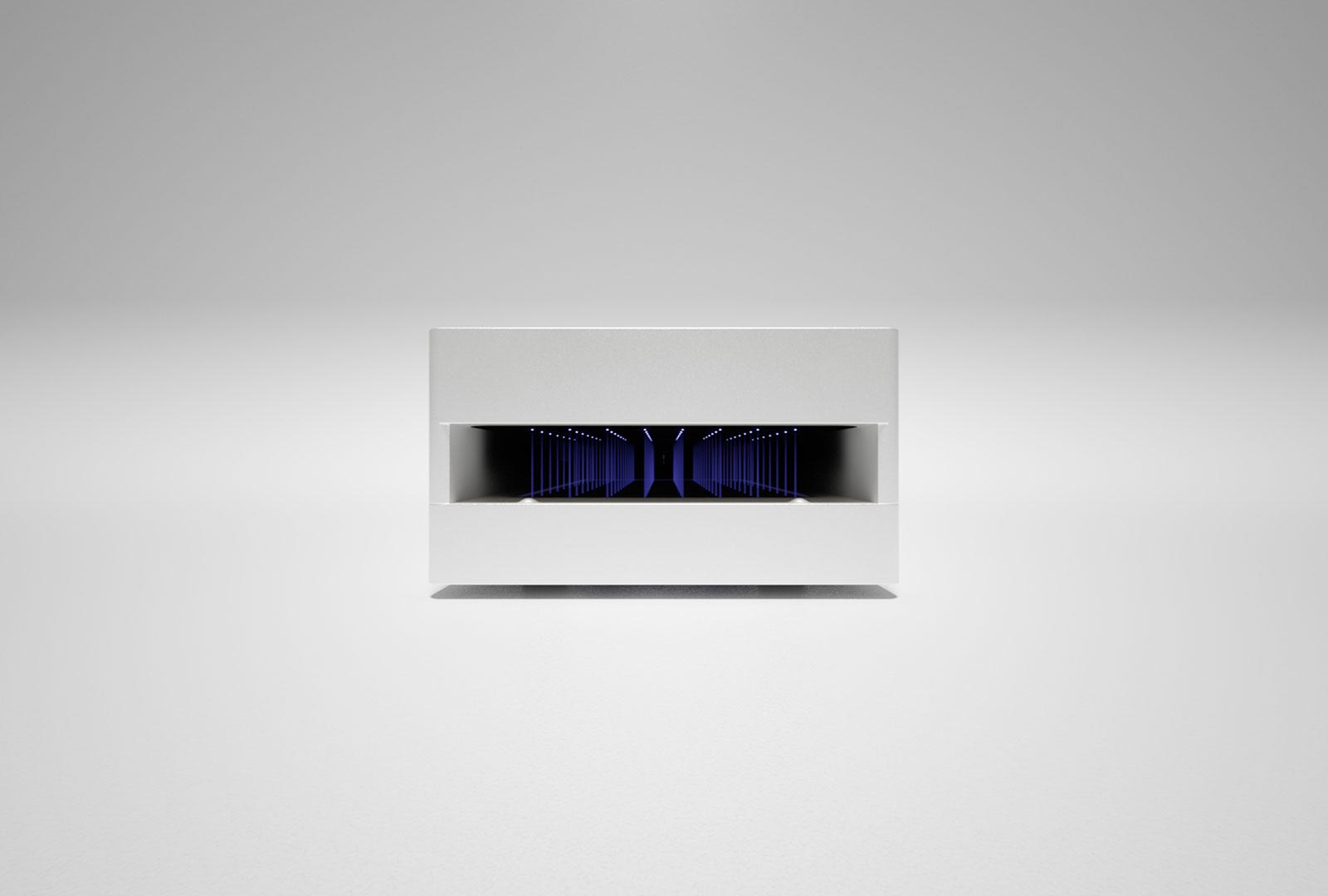

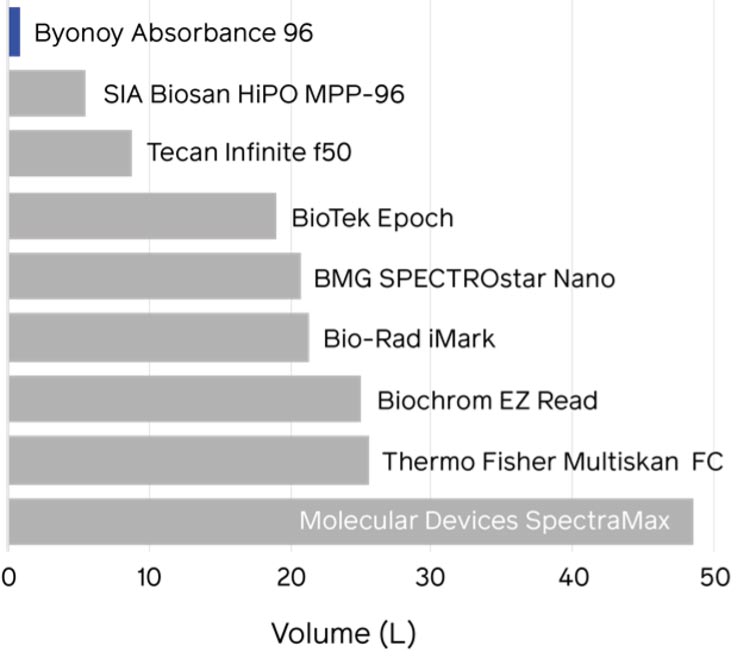

A solid-state reader is characterized by an ultra-compact design, meaning it can be used flexibly within and between laboratories and can be easily integrated into existing laboratory structures, all while taking up minimal amounts of highly valuable laboratory space. Its potential can be seen in Fig. 2, where typical readers on the market are compared by their volume, which is a good indicator of their space consumption.

Figure 2: Size comparison of typical readers on the market

As can be seen in Fig. 2, Absorbance 96, the first SSR on the market, has a drastically reduced footprint compared to other readers. This size differentiation is due to the absence of any scanning mechanics or motors, which precludes the necessity for a large housing and complex mechanical arrangement.

The compactness of an SSR also allows for new applications. This comes from the fact that a given assay can be conducted in the desired environment, such as an incubator, under a sterile fume hood, or on a shaker. This means, for example, that experiments in such enclosed spaces can be monitored and measured internally with such a device for the first time.

Portability

Due to its compact form and highly robust design, the SSR is the first portable microplate reader on the market (Fig. 3). It allows highly flexible use within and outside laboratories. Therefore, the SSR is particularly well suited to decentralized or mobile laboratories. Whether in a tent or on a tailgate, measurements can be taken wherever a laptop or tablet is available.

Additionally, the portability of such a reader allows for new, on-site applications that weren’t previously possible. The ease of transportation and robustness allows it to be taken into the field, thereby reducing the need for sample transportation, as readout can be performed on-site. This kind of portability could also be a significant factor when trying to establish mobile laboratories or decentralized testing of large populations, as the flexibility to change locations and measure on-site would be available.

Figure 3: Byonoy Absorbance 96 with a footprint as small as the microplate

Measurement time

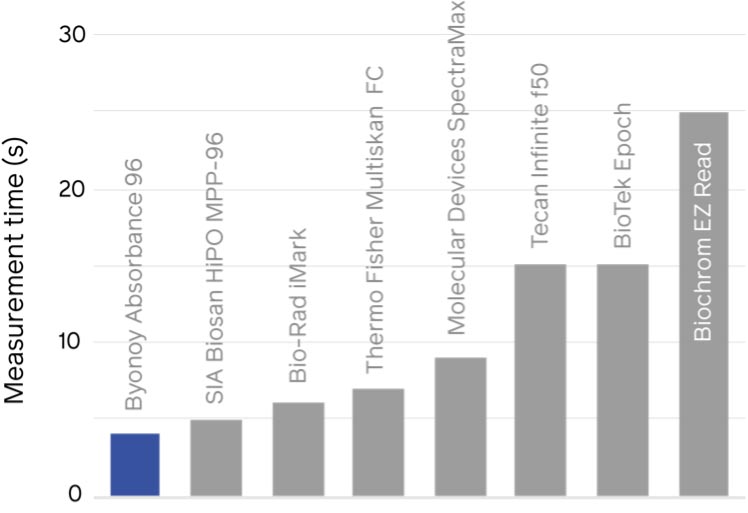

In a solid-state reader, all wells can be measured almost simultaneously, and the measurement time is only limited by the actual readout, not by the scanning time. A fast measurement time (a few seconds) is normally not crucial to perform an assay. However, it has a big impact on the user experience, as the user has to wait for the measurement to finish. Fig. 4 shows the typical measurement time of different readers on the market for a standard 96-well plate. These times reflect the time taken to measure an entire 96-well plate at a single wavelength.

Figure 4: Measurement time of different microplate readers on the market

Easy installation and maintenance-free

Other important features of the solid-state Reader are its easy installation and its robustness due to the absence of moving parts. The installation process of traditional readers is time-consuming and sometimes cost-intensive: transport locks, which prevent the mechanical parts from breaking during transit, must be removed. Afterward, the reader must be calibrated before it can be used. Both the unpacking and installation can be time and labor-intensive and are often handled by a technician from the manufacturer. With an SSR, neither trans-portation security nor a post-transport calibration is necessary, as there are no moving parts. SSRs can be used straight away after unboxing.

Apart from the initial setup and calibration requirements, traditional readers require regular maintenance to ensure that all the moving parts are in working order and, for example, to ensure that the detection units are correctly spatially calibrated to avoid issues with reproducibility, similar to those already mentioned. Although newer plate readers have become more robust, they still have these calibration requirements. An SSR, on the other hand, does not require extensive calibration, and, due to the fixed design of the detection units, does not need to be aligned or spatially calibrated by a technician.

Sustainability

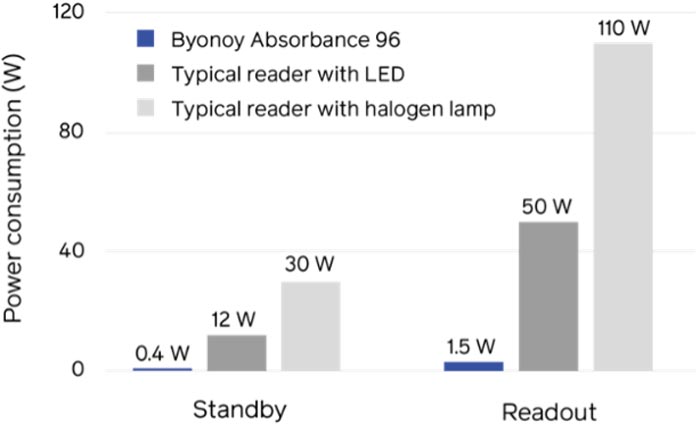

Another consequence of the solid-state design is its positive impact on the sustainability of the reader. This starts in the manufacturing process, where less material is used to fabricate the reader. Next, the transportation of parts for the manufacturer or the finished reader itself is more environmentally sustainable. Lastly, because the power consumption is a fraction of that of traditional readers, the environmental footprint of these readers is minimized during their whole lifetime. Another consequence of the solid-state design is its positive impact on the sustainability of the reader.

Since the LED can be lit at very low power and no motors are utilized for scanning, the power delivery for the reader is carried out fully via a USB connection to the computer and is characterized by its efficiency. The comparison in Fig. 5 for typical readers on the market shows the leap forward of the Absorbance 96.

Figure 5: Power consumption of different reader types on the market

Conclusion

Since their inception, the gradual evolution of microplate readers over the last few decades has yielded little change. The solid-state reader, however, represents a revolutionary step toward a new category of microplate and is a complete departure from traditional readers. This extends not only to the functionality and reliability of the reader but also to its applications. This leap forward is best seen in the increase in usability of such readers, their portability and lack of restriction to a fixed location, measurement time, maintenance-free usage, and environmental sustainability.